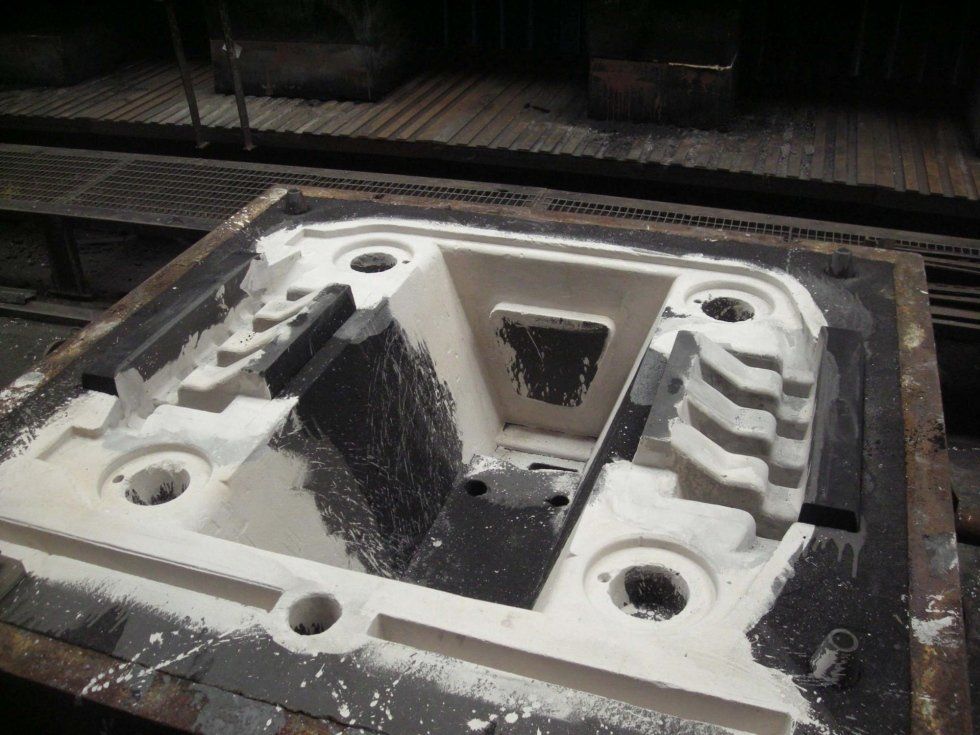

HIGH-QUALITY PROCESSING WITH THE NO-BAKE SYSTEM

The manual moulding department at Fonderia Quaglia & Colombo, equipped with a continuous mixer with a capacity of 20 tonnes per hour, is dedicated to the production of large castings or very small batches. The large fleet of flasks available allows us to meet any requirements in terms of shapes and sizes for castings weighing up to 6 tonnes.

Even today, when technology has enabled the automation of almost the entire production, for the most complex and larger castings, we rely solely on the expertise of our moulders and rammers. Fonderia Quaglia & Colombo's commitment has always been, and will always be, to guarantee the highest quality in every operation carried out.

Constant

technological and production improvement

In over 60 years of history for the Milanese company, founded in the 1930s, there has always been a focus on constant technological and production improvement, to offer an increasing number of services to each customer, without compromising on quality.

Choosing to rely on Quaglia & Colombo is, therefore, the best way to find expertise and professionalism. In addition to the manual No-Bake moulding department, there are also the automatic No-Bake moulding, green sand moulding, laboratories, core shop, and pattern shop.